| Sign In | Join Free | My chinalane.org |

|

| Sign In | Join Free | My chinalane.org |

|

| Categories | Auto Injection Molding Machine |

|---|---|

| Brand Name: | Taihong |

| Model Number: | plastic injection molds |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 20sets/month |

| Delivery Time: | 45days |

| Packaging Details: | Export standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer' s requirement. |

| Mold material: | 45#,50#,P20,H13, 718 2738, NAK80, S136, SKD61 etc. |

| Runner: | Cold/Hot runner |

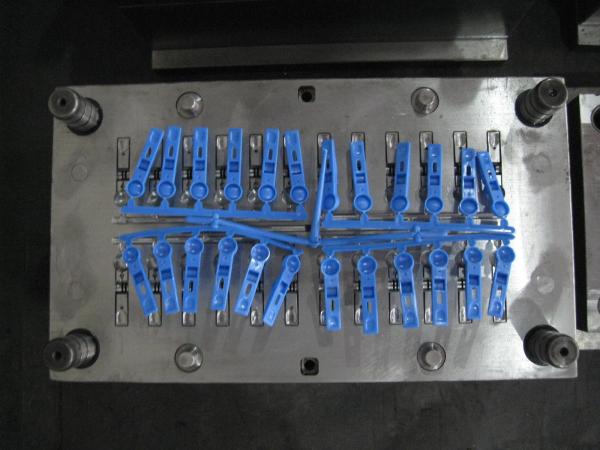

| Cavity: | Multi cavities |

| Company Info. |

| Ningbo Haijiang Machinery Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

| Item | Description |

| Product Name | Plastic part |

| Working Process | Plastic injection |

| Material | ABS, PC, PP, PS, POM, PMMA |

| Mould Base Material | LKM, FUTA, HASCO, DME, etc. or as per customer' s requirement. |

| Surface treatment | Polishing plating |

| Color | Red, blue, green, yellow |

| Packing | Inner-Plastic Bag; Outer -Standard Carton Box. |

| Usage | All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more |

| Quality Control | Conducted by ISO9001 |

| Cavity Number | Single cavity, Multi Cavity, based on customer' s requirement. |

| Applications | auto,motorcycle,industry,ariculture,mine,furniture,elevator,etc |

| Equipments | CNC,EDM,ArgieCharmilles,Milling Machine,3D CMM, Projector,HG,Injection Machine |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| Inspection | IQC, IPQC,FQC,QA |

Plastic Mold (Mould) production process:

1. 3D drawing/Samples for quotation: According to 3D drawing or samples for quotation.

2. Negotiations: Including the price of moulds, moulds sizes, material for cores & cavities, weight of product, product color, payment, moulds lifetime, delivery, etc.

3. Purchasing Order : After the customer confirming the mould design and quotation.

4. Making mold(moulds): Confirm drawing, start to do DFM, mold flows and mold detail agreed with the customer, start producion.

5. Production schedule: Every week we will feedback to the customer about the mold progress(picture).

6. Sample shoot: We provide the moulds test samples for confirmation(about 10-15 piece), we will start mass production when get your signature samples.

Our mold service :

| Quotation | Fast reply, in 2 working days |

| Pre-production proposal | We offer professional & practical solution for your investment |

| OEM/ODM service | We would provide OEM/ODM service as your request |

| Mold process report | Weekly report, mould processing photos and samples for your checking |

| Approval | 2D/3D mould drawing & mould manufacturing schedule for customer’s approval |

| Mould Design | According to customer's products drawings or samples |

| Spare parts | wearing spare parts provided |

| After sale service | Provide |

|