| Sign In | Join Free | My chinalane.org |

|

| Sign In | Join Free | My chinalane.org |

|

| Categories | Particle Board Production Line |

|---|---|

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Payment Terms: | L/C, T/T |

| Packaging Details: | Wooden package |

| Designed capacity: | 300-1500 m³/d |

| Press size: | 4-8 ft |

| Press speed: | 1000-1800 mm/s |

| Thickness range: | 1..8-40 mm |

| Company Info. |

| Suzhou Forestry Technologies Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

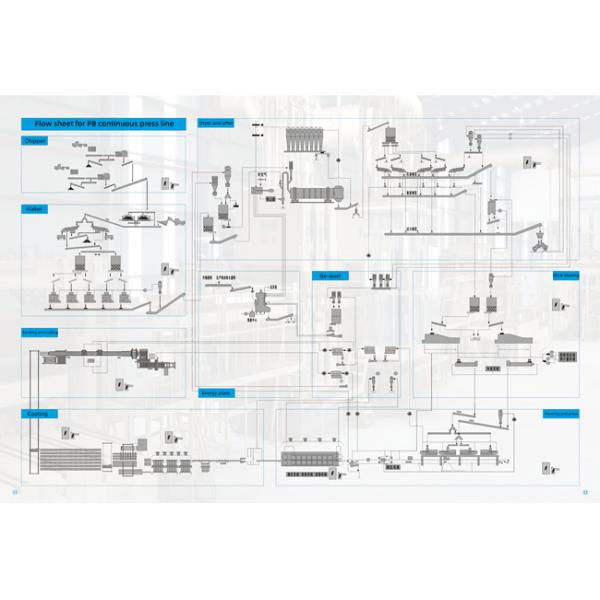

Particle Board Continuous Press Production Line with Capacity of 300~1500 cbm per day

We could provide customized project construction for wood-based panels, from raw wood to chips preparation, from fiber and flakes

making to finished raw board, from sanding and cut-to-size to inspection &

packing, which is one-stop whole process factory solutions.

At the same time, we provides full-cycle product service support from factory setup and installation, commissioning and test running, process

optimization, remote maintenance to spare parts support.

| Item | Unit | PB/SSB | OSB/LSB |

| Designed capacity | m3/d | 400-1500 | 300-1500 |

| press size | ft | 4-8 | 4-8 |

| Press speed | mm/s | Max.1000 | Max.1000 |

| Thickness range | mm | 6-40 | 6-40 |

1 High energy efficiency and waste energy can be recycled to save energy

2 More safe due to low oxygen drying to prevent fire

3 Flaker shape will be well maintained

4 Stable flaker moisture

5 Large unit capacity

1 Large capacity and good performance

2 Frame screen box makes strong and durable

3 Brilliant elastic vibration support

4 Perfect rotary balance technology

5 Self-clean system with jumping balls

6 Stable running and long lifetime

7 Compact structure and less space required

1 Feeding crosswise— real-time regional control technology

2 Volume equal silo— ensure consistent bulk density

3 Aerodynamics— perfect balance of positive/negative pressure airflow

4 Airflow regulation system— artful combination of vertical& horizontal adjustment

5 Airflow surface forming— fine and smooth surface

6 Advanced control technology— high precision lengthwise and crosswise density

(photo of mechanical forming station)

1 Crosswise feeding— real-time regional control technology

2 More delicate diamond rollers— ensure forming precision

3 Positive/negative pressure assistant airflow— ensure better fine surface

4 Core cage roller forming— uniform core mat structure

5 Advanced control technology— high precision lengthwise and crosswise density

|